Power factor correction (PFC) is a crucial concept in the world of LED drivers and modern electrical systems. As energy efficiency becomes increasingly important, understanding how PFC works and its significance in LED applications can help businesses and consumers make informed decisions about their lighting solutions.

What Is Power Factor?

Power factor is a measure of how effectively electrical power is converted into usable work output. It is expressed as a value between 0 and 1, where 1 indicates perfect efficiency. A low power factor means that more energy is wasted, often in the form of heat, and places additional strain on the electrical grid.

In the case of LED drivers, an ideal power factor ensures that the driver draws current in a smooth and efficient manner, reducing energy losses and improving overall performance.

Why Is Power Factor Important in LED Drivers?

LED lighting systems are known for their energy efficiency, but without proper power factor correction, they can inadvertently contribute to energy inefficiency. A poor power factor in LED drivers can lead to:

Higher Electricity Costs: Increased energy consumption due to wasted power.

Harmonic Distortion: Interference with other electrical equipment in the system.

Overburdened Grid Infrastructure: Additional strain on the power supply network, particularly in large installations.

By incorporating power factor correction, LED drivers can mitigate these issues, ensuring both cost savings and system reliability.

There are two main types of PFC used in LED drivers:

Passive PFC: Uses passive components like inductors and capacitors to correct the power factor. This method is simple and cost-effective but less efficient for high-power applications.

Active PFC: Employs active electronic circuits to improve the power factor dynamically. This approach is more precise and efficient, making it ideal for advanced LED systems and industrial applications.

Benefits of Power Factor Correction in LED Drivers

Energy Efficiency: Minimizes energy wastage and ensures optimal performance.

Cost Savings: Reduces electricity bills and operating costs over time.

Improved Reliability: Protects other electrical equipment by minimizing interference.

Regulatory Compliance: Meets international standards for power efficiency and environmental responsibility.

Sustainability: Supports global efforts to reduce carbon emissions and conserve energy resources.

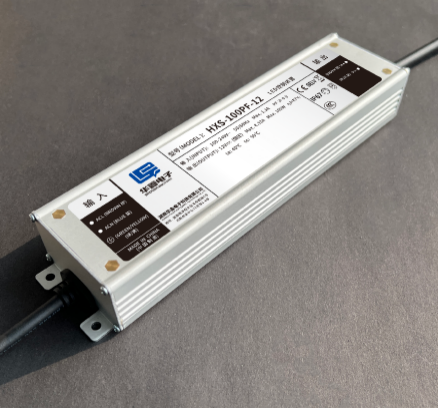

How Our LED Drivers Utilize PFC

Our LED drivers are designed with advanced power factor correction technology to deliver top-notch performance in various applications. With active PFC circuits, our products achieve high power factor values, typically above 0.95, ensuring minimal energy loss and compliance with stringent global standards.

Whether it’s residential, commercial, or industrial lighting, our LED drivers are engineered to maximize efficiency, reliability, and sustainability.

Conclusion

Power factor correction is not just a technical specification; it is a critical feature that directly impacts the efficiency and reliability of LED lighting systems. By choosing LED drivers with robust PFC technology, you can enjoy significant cost savings, superior performance, and contribute to a greener future.

For more information on our LED drivers and their power factor correction capabilities, please Contact Us today!

Leave a Reply